This article presents a worked example on the design of doubly reinforced concrete beam to EC2

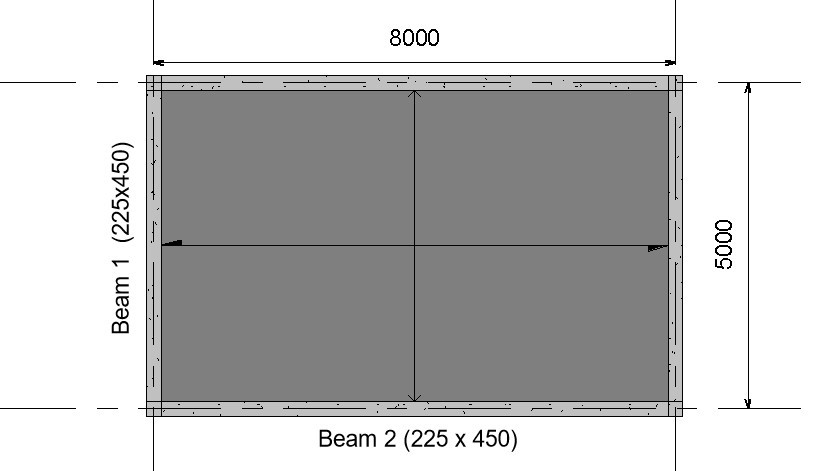

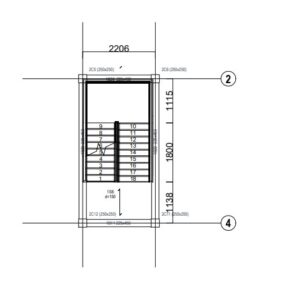

The image below shows the Plan view of a reinforced concrete structure, use the data given below to design Beam 2

Design Data:

Variable load on slab = 5KN/m2

Finishes = 1.5KN/m2

Unit weight of concrete = 24KN/m3

Compressive strength of concrete (fck) = 30N/mm2

Characteristic Strength of main reinforcement (fyk) = 500N/mm2

Characteristic Strength of Shear reinforcement (fyv) = 500N/mm2

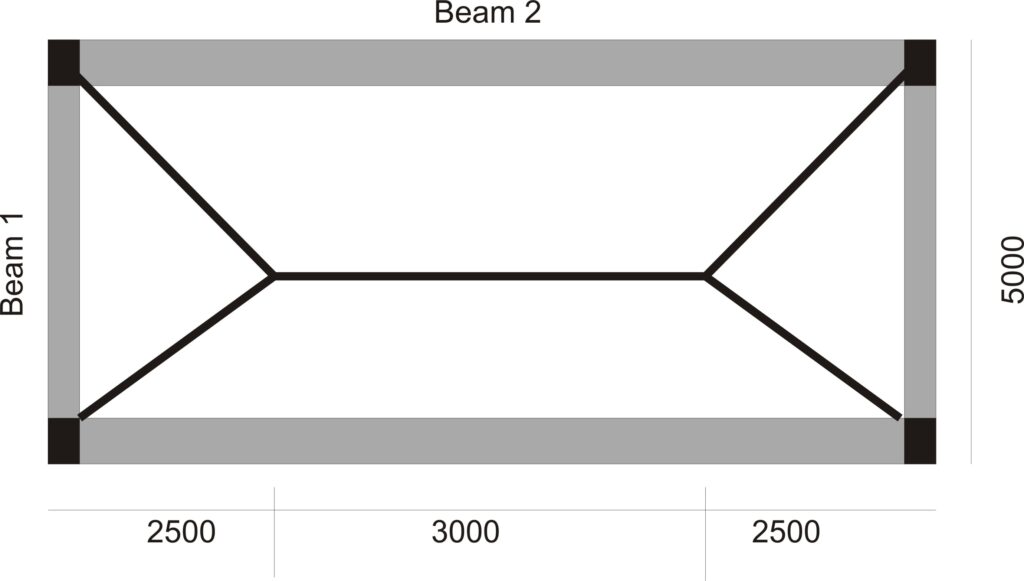

To design Beam 2, we will first distribute the slab loads on the beam and then analyze the beam to compute its internal forces. As shown in fig (2) below the tributary area of slab loads on beam 2 is a trapezium, hence we compute and distribute the slap loads on it as follows:

However, to understand the process of distributing slab load to beams in detail, read, “Distribution of Slab loads to beams.”

fig (2)

Analysis

Permanent Load

Characteristic Self-weight of slab = 0.2 x 24 = 4.8KN/m2

Partition Load on Slab = 1.5KN/m2

Characteristic Permanent Load on Slab = 4.8 + 1.5 = 6.38KN/m2

Area of Slab load Supported by Beam 2 = (0.5 x (8 + 3) x 2.5)/8 = 1.73m2

Permanent Load of Slab on Beam 2 = 1.72 x 6.38 = 10.97KN/m

Self-weight of beam = 0.23 x 0.45 x 24 = 2.48KN/m

Total Permanent Load on beam = 10.97 +2.48 = 13.5 KN/m

Variable Load

Variable load on slab = 5KN/m2

Area of Slab load Supported by Beam 2 = (0.5 x (8 + 3) x 2.5)/8 = 1.73m2

Characteristic Variable Load of Slab on Beam 2 = 1.258 x 5 = 8.59KN/m

Total Design Load

Ultimate Load acting on beam 2 = 1.35(13.5) + 1.5(8.59) = 31.11KN/m

Computation of Internal Forces:

The beam is assumed to be simply supported for ease of analysis.

M = w x L2/8 = 31 x 82/8 = 248KNm

V = W x L/2 = 31 x 8/2 = 124KN

Design

flexural strength design

- Calculate the effective depth

Assumptions

Cover = 25mm

Main reinforcement diameter = 16mm

Diameter of links = 10mm

Effective depth = h-c-ᴓ-ᴓ/2

= 450-25-10-16/2

= 407mm

2) Check whether section is to be designed as singly or doubly reinforced beam

$

K\,=\,\,\frac{M}{bd^2f_{ck}}

$

$

K\,=\,\,\frac{248×10^6}{225×450^2×30}

$

= 0.22

Since K (0.22) > K’ (0.168); design as doubly reinforced.

3) Calculate the lever arm (Z)

$

Z\,\,=\,\,d\left( 0.5+\sqrt{\text{0.25}-\,\,\frac{K’}{1.134}} \right)

$

$

Z\,\,=\,\,407\left( 0.5+\sqrt{\text{0.25}-\,\,\frac{0.22}{1.134}} \right)

$

Since 333.4 < 0.95d (386.7): use Z = 333.4

4. Calculate the area of compression steel required.

$

A_{sc\,\,=\,\,\frac{M_{Ed\,\,}-\,\,0.168f_{ck}bd^2}{0.87f_{yk}\left( d-d’ \right)}}

$

$

A_{sc\,\,=\,\,\frac{248×10^6-\,\,0.168 x 30 x 225 x 407^2}{0.87 x 500\left( 407-43 \right)}}

$

Asc = 379.9mm2

Provide 2Y16 (399.9mm2)

5. Calculate the area of tensile steel

$

A_{st}\,\,=\,\,\frac{K_{bal}f_{ck}bd^2}{0.87f_{yk}Z}+A_{sc}

$

$

A_{st}\,\,=\,\,\frac{0.168 x 30 x 225 x 407^2}{0.87 x 500 x 333.4}+379.9

$

Ast = 1675.2mm2

Provide 9Y16 (1799mm2)

Shear Strength Design

- Check whether the concrete section can resist the shear force without shear reinforcement

VRdc = (0.12K(100ρLfck)1/3 + K1σcp) bwd

K = (1 +√200/d) = 1 + (200/407)0.5 = 1.7

ρL = Asl/bwd = 1799/225 x 407 = 0.018

VRdc = (0.12 x 1.7 (100 x 0.018 x 30) 1/3) 225 x 407

VRdc = 78.5KN

Since VRdc (78.5KN) is less than VEd (124KN) then shear reinforcement has to be designed for.

2. Calculate the shear resistance using ϴ = 22

VRdmax(22) = 0.124bwd(1 – fck/250)fck

= 0.124 x 225 x 407 (1 – 30/250)30

= 299.8KN

Shear resistance of links at ϴ = 22 is adequate

3. Calculate Asw/s at ϴ = 22

$

\frac{A_{sw}}{s}\,\,\,\,=\,\,\frac{V_{Ed}}{0.78xf_{yk}d\cot 22}

$

$

\frac{A_{sw}}{s}\,\,\,\,=\,\,\frac{124×10^3}{0.78x407x500\cot 22}

$

$\frac{A_{sw}}{s}\,\,\,\,$ = 0.3

4. Check whether $\frac{A_{sw}}{s}\,\,\,\,$ satisfy the minimum requirement specified by the code.

$$

\frac{A_{sw\min}}{s}\,\,\,\,=\,\,\frac{0.08x\sqrt{f_{ck}}xb_w}{f_{yk}}

$$

$$

\frac{A_{sw\min}}{s}\,\,\,\,=\,\,\frac{0.08x\sqrt{30}x225}{500} $$

= 0.19

Since Asmin/s (0.19) is less than As/s (0.3), shear reinforcement is greater than the required minimum area of reinforcement.

5) Calculate shear link reinforcement spacing requirement

Assume two-legged shear reinforcement of 10mm is to be used.

Area of 10mm shear reinforcement = 78.58mm2

Area of two-legged 10mm links = 2x 78.58 = 157mm2

157/s = 0.3

s = 157/0.3

s = 497.9

6) Check whether maximum spacing requirement is satisfied

Smax = 0.75xd

= 0.75 x 407

= 305mm

Since the maximum spacing (305mm) is less than the calculated spacing of links (497.9mm), the maximum spacing limit governs the design.

provide Y10 @ 300mm spacing.

Read also: Design of a Singly Reinforced Beam to Eurocode 2

Deflection Check

- Calculate the actual span-effective depth ratio

Span/depth ratio = 8000/407 = 19.7

2. Calculate the limiting Span-effective depth ratio

l/d = K[11 + 1.5√fck ρ0/ρ + 3.2√fck (ρo/ρ – 1)3/2] if ρ ≤ ρo

l/d = K[11 + 1.5√fck ρo/ρ + 3.2√fck √ρo/ρ ] if ρ > ρo

ρ = Asrequired/b x d

ρ = 1675.2/225 x 407

= 0.018

ρo = 10-3√fck

ρo = 10-3√30

= 0.005

K = 1 (for simply supported)

Since ρ > ρo = then we will use

l/d = K[11 + 1.5√fck ρo/ρ + 3.2√fck √ρo/ρ ]

l/d = [11 + 1.5√30 0.005/0.019 + 3.2√30 √0.005/0.019]

= 14.3mm

Since actual span-effective depth ratio (19.7) is greater than the limiting span-effective depth ratio (14.3), the beam fails deflection check.

NB: Since the beam fails deflection check, it shall be resized by increasing its depth so as to reduce the span-depth ratio. Another effective solution is to design the beam as encastre beam fixed at both ends; this will reduce its overall deflection as well as its sagging moment which will result to the decrease in the area of tensile steel provided for flexural strength of the member.

Hi there to every one, since I am truly keen of reading this website’s

post to be updated regularly. It contains fastidious stuff.

Fabulous, what a blog it is! This weblog provides helpful facts to

us, keep it up.

It’s a shame you don’t have a donate button! I’d definitely donate to this superb blog!

I guess for now i’ll settle for book-marking and adding your RSS feed to my Google account.

I look forward to brand new updates and will share this blog with my Facebook group.

Chat soon!

I like the valuable info you provide in your

articles. I’ll bookmark your weblog and check again here frequently.

I am quite sure I will learn many new stuff right here! Good luck for the next!

Yesterday, while I was at work, my cousin stole

my apple ipad and tested to see if it can survive a thirty foot

drop, just so she can be a youtube sensation. My iPad is now

broken and she has 83 views. I know this is totally off topic but I

had to share it with someone!

My brother suggested I might like this website. He was entirely right.

This post actually made my day. You cann’t imagine just how much

time I had spent for this information! Thanks!

I’m not sure where you’re getting your information, but great topic.

I needs to spend some time learning much more or understanding more.

Thanks for excellent information I was looking for this

information for my mission.

An outstanding share! I have just forwarded this onto a colleague who had been conducting a little homework on this.

And he in fact bought me breakfast due to the fact that I found

it for him… lol. So let me reword this…. Thanks for the meal!!

But yeah, thanx for spending the time to discuss this matter

here on your website.

Very good blog post. I absolutely appreciate this website. Keep writing!

Magnificent beat ! I would like to apprentice

while you amend your web site, how can i subscribe for a blog site?

The account aided me a acceptable deal. I had been a little bit acquainted of this your broadcast provided bright clear

idea

Very great post. I just stumbled upon your weblog and

wished to say that I’ve truly loved browsing your weblog posts.

After all I’ll be subscribing to your rss feed and I’m hoping you write again very soon!

Hey! I know this is kinda off topic but I’d figured I’d ask.

Would you be interested in exchanging links or maybe

guest authoring a blog article or vice-versa? My blog addresses a lot of the

same topics as yours and I believe we could greatly benefit from each other.

If you happen to be interested feel free to shoot me an email.

I look forward to hearing from you! Terrific blog by the way!

I am sure this post has touched all the internet users, its really really pleasant post on building up new

weblog.

My spouse and I stumbled over here different web page and

thought I might as well check things out. I like what I see so i

am just following you. Look forward to looking into your web page for a second time.

Nice post. I was checking continuously this weblog and I am inspired!

Extremely helpful information specifically the last

part 🙂 I care for such information much. I was looking for this certain information for a long time.

Thanks and best of luck.

If some one wants expert view regarding blogging then i recommend

him/her to visit this blog, Keep up the fastidious work.

I’m gone to tell my little brother, that he should also visit this web site on regular

basis to take updated from hottest gossip.

Your style is unique compared to other folks I’ve read stuff from.

Thank you for posting when you have the opportunity, Guess I’ll just bookmark this page.

If you desire to obtain a great deal from this

piece of writing then you have to apply these techniques to your

won weblog.

There’s definately a great deal to find out about this

issue. I love all the points you have made.

Thanks for ones marvelous posting! I quite enjoyed reading it, you are a great author.

I will be sure to bookmark your blog and will come back sometime soon. I want

to encourage continue your great writing, have a nice weekend!

Hello there! This post couldn’t be written much better!

Reading through this post reminds me of my previous roommate!

He continually kept talking about this. I will send this post to him.

Pretty sure he’s going to have a good read.

Thanks for sharing!

Hey would you mind letting me know which web host you’re utilizing?

I’ve loaded your blog in 3 completely different web browsers and I must say this blog loads

a lot quicker then most. Can you recommend a good web hosting provider at a reasonable price?

Cheers, I appreciate it!

My brother recommended I might like this web site.

He used to be entirely right. This post actually made my day.

You cann’t consider just how much time I had spent for this information! Thanks!

Since the admin of this website is working, no hesitation very quickly it will be well-known, due to its quality contents.

WOW just what I was searching for. Came here by searching for website

Hello! This is my first visit to your blog! We are a collection of volunteers

and starting a new project in a community

in the same niche. Your blog provided us beneficial information to work on. You have done a outstanding job!

My family always say that I am wasting my time here at web,

except I know I am getting experience daily by reading such nice articles.

After I initially left a comment I seem to have clicked

the -Notify me when new comments are added- checkbox and now every time a comment is added

I receive 4 emails with the exact same comment.

There has to be an easy method you are able to remove me from

that service? Many thanks!

Undeniably believe that which you stated.

Your favorite reason seemed to be on the web the simplest thing to be aware of.

I say to you, I definitely get annoyed while people consider worries that

they plainly don’t know about. You managed to hit the nail

upon the top as well as defined out the whole thing without having side effect , people can take a signal.

Will likely be back to get more. Thanks

Hi! I’ve been following your site for a long time now and finally

got the bravery to go ahead and give you a shout out from

Houston Texas! Just wanted to tell you keep up the great job!

I am genuinely thankful to the owner of this

web site who has shared this enormous post at here.

Pretty nice post. I just stumbled upon your weblog and wished to mention that I’ve really loved browsing your weblog

posts. After all I’ll be subscribing for your feed and I hope you write again very soon!

Way cool! Some very valid points! I appreciate

you writing this write-up and the rest of the website

is also very good.

Very nice article. I definitely appreciate this website.

Thanks!

Valuable information. Fortunate me I found your site accidentally,

and I’m shocked why this twist of fate did not came about in advance!

I bookmarked it.

Simply wish to say your article is as astonishing.

The clarity on your submit is just nice and i can suppose you’re a professional in this subject.

Fine together with your permission allow me to clutch your RSS feed to stay updated

with drawing close post. Thanks a million and please continue the rewarding work.

Howdy just wanted to give you a brief heads up and let you know a few of the pictures aren’t loading correctly.

I’m not sure why but I think its a linking issue.

I’ve tried it in two different browsers and both show the same results.

I really like it when folks get together

and share opinions. Great blog, keep it up!

Hey! Someone in my Facebook group shared

this site with us so I came to check it out.

I’m definitely loving the information. I’m bookmarking

and will be tweeting this to my followers! Outstanding blog and great design and style.

hello there and thank you for your information – I have

certainly picked up anything new from right here. I did however expertise some technical points using this website, since

I experienced to reload the site lots of times previous to I could get it

to load properly. I had been wondering if your hosting is OK?

Not that I am complaining, but sluggish loading

instances times will often affect your placement in google and can damage your high

quality score if ads and marketing with Adwords. Anyway I am adding this RSS to

my e-mail and can look out for much more of your respective interesting content.

Ensure that you update this again very soon.

whoah this blog is magnificent i love reading your articles.

Keep up the great work! You recognize, a lot of individuals are hunting round for this information, you can aid them greatly.

I think this is one of the most important information for me.

And i am glad reading your article. But wanna remark on few

general things, The website style is ideal, the

articles is really excellent : D. Good job, cheers

Hello everyone, it’s my first go to see at this website, and article is actually

fruitful for me, keep up posting these types of content.

After looking into a number of the blog articles on your web site, I seriously appreciate your way of blogging.

I book marked it to my bookmark webpage list and

will be checking back in the near future. Take a look at my web site too and let me know what

you think.

Thanks on your marvelous posting! I seriously enjoyed reading it,

you will be a great author.I will make certain to bookmark your blog and will eventually come back someday.

I want to encourage yourself to continue your great posts, have a

nice evening!

Hi there, this weekend is good designed for me, because this point

in time i am reading this great educational paragraph here at my home.

First of all I would like to say superb blog! I had a quick question that I’d

like to ask if you don’t mind. I was interested to know how

you center yourself and clear your head prior to writing.

I’ve had a difficult time clearing my thoughts in getting my ideas

out there. I truly do enjoy writing but it just seems like the first

10 to 15 minutes are lost simply just trying to figure out how to begin. Any recommendations or hints?

Thank you!

Just desire to say your article is as amazing.

The clearness on your publish is simply spectacular and

i can suppose you’re knowledgeable in this subject.

Fine together with your permission allow me to take hold of your RSS feed to keep up to date with coming near

near post. Thanks 1,000,000 and please carry on the

gratifying work.

This piece of writing is truly a pleasant one it helps new internet visitors, who are wishing

for blogging.

Excellent blog here! Also your web site loads

up fast! What host are you using? Can I get your affiliate link to

your host? I wish my site loaded up as quickly as

yours lol

Hi outstanding website! Does running a blog such as this require a lot of work?

I’ve absolutely no expertise in programming but I had been hoping to

start my own blog in the near future. Anyhow, if you have any suggestions or tips for new blog owners please share.

I know this is off topic nevertheless I simply had to ask.

Thanks a lot!

I was able to find good information from your

articles.

I visit day-to-day a few web pages and blogs to read posts, but this weblog gives feature based writing.

hi!,I like your writing very much! percentage we be in contact extra about your article on AOL?

I require an expert on this area to solve my problem.

May be that’s you! Taking a look forward to look you.

Hello, i think that i saw you visited my site thus i came to

“return the favor”.I’m attempting to find

things to improve my site!I suppose its ok to use

some of your ideas!!

I know this if off topic but I’m looking into starting my own weblog and was wondering what all is required to get setup?

I’m assuming having a blog like yours would cost a pretty penny?

I’m not very web smart so I’m not 100% positive.

Any recommendations or advice would be greatly appreciated.

Thanks

Does your site have a contact page? I’m having

problems locating it but, I’d like to shoot you an e-mail.

I’ve got some ideas for your blog you might

be interested in hearing. Either way, great website

and I look forward to seeing it expand over time.

An impressive share! I’ve just forwarded this onto a coworker who was doing a little homework on this.

And he actually ordered me dinner simply because I found it for him…

lol. So let me reword this…. Thank YOU for the meal!! But yeah, thanx for spending some time

to discuss this subject here on your website.

I absolutely love your blog.. Great colors & theme. Did

you develop this site yourself? Please reply back

as I’m trying to create my very own site and would love to

know where you got this from or just what the theme is called.

Thank you!

Its not my first time to visit this web page, i am visiting this

web site dailly and get nice information from here all the

time.

I am really inspired along with your writing abilities as neatly as

with the structure for your weblog. Is that this a paid subject or did

you customize it your self? Either way stay up the nice

quality writing, it’s uncommon to see a great

weblog like this one these days..

We absolutely love your blog and find most of your post’s to

be just what I’m looking for. Would you offer

guest writers to write content for yourself? I wouldn’t mind composing a post or elaborating

on many of the subjects you write concerning here.

Again, awesome site!

constantly i used to read smaller content which also clear their motive, and that is

also happening with this paragraph which I am reading at this time.

Thanks on your marvelous posting! I definitely enjoyed reading it, you

are a great author. I will make sure to bookmark your blog and definitely will come

back later on. I want to encourage one to continue your great job, have a nice evening!

Hey there are using WordPress for your blog platform?

I’m new to the blog world but I’m trying to get started and create my own. Do you

need any coding knowledge to make your own blog?

Any help would be greatly appreciated!

Hey! I just wanted to ask if you ever have any problems with hackers?

My last blog (wordpress) was hacked and I ended up losing several weeks of hard work due to no backup.

Do you have any solutions to protect against hackers?

Hello there, There’s no doubt that your web site could

possibly be having browser compatibility issues. Whenever I take a

look at your website in Safari, it looks fine

however, when opening in I.E., it has some overlapping issues.

I just wanted to provide you with a quick

heads up! Besides that, great website!

Good information. Lucky me I came across your website by accident

(stumbleupon). I’ve book-marked it for later!

Your article helped me a lot, is there any more related content? Thanks!

I really love your website.. Great colors & theme.

Did you make this site yourself? Please reply back as I’m wanting

to create my own personal site and would love to find out where you got this from or just what

the theme is named. Appreciate it!

When some one searches for his essential thing, therefore he/she desires

to be available that in detail, so that thing is maintained over here.

Great post. I was checking constantly this weblog and I am inspired!

Very useful information specially the ultimate section :

) I maintain such info a lot. I was seeking this certain info for a long time.

Thanks and best of luck.

What’s Taking place i am new to this, I stumbled upon this I have found It positively helpful and it has aided me out loads.

I’m hoping to give a contribution & assist other users like its

aided me. Great job.

There is definately a lot to learn about this

subject. I really like all the points you’ve made.

Whoa! This blog looks just like my old one! It’s on a completely different topic but it has

pretty much the same layout and design. Great choice of colors!

Thank you a bunch for sharing this with all of us you really understand what you’re speaking about!

Bookmarked. Please also visit my website =). We may have a hyperlink exchange arrangement between us

Asking questions are in fact fastidious thing if

you are not understanding something fully, but this post offers nice

understanding even.

Yes! Finally something about website.

Excellent weblog right here! Additionally your site loads up very fast!

What web host are you the usage of? Can I am getting your associate link to your

host? I desire my web site loaded up as quickly as yours lol

Very descriptive article, I enjoyed that a lot.

Will there be a part 2?

I’ve been browsing online more than three hours today,

yet I never found any interesting article like yours.

It is pretty worth enough for me. In my opinion, if all site owners and bloggers made good content

as you did, the web will be a lot more useful than ever before.

Howdy! This post could not be written any better!

Reading through this post reminds me of my good old

room mate! He always kept talking about this. I will forward this write-up to him.

Pretty sure he will have a good read. Many thanks for sharing!

Heya i’m for the first time here. I came across this board and I find It really useful & it helped me out much.

I hope to give something back and aid others like you aided me.

Hmm is anyone else encountering problems with the

pictures on this blog loading? I’m trying to find out if its a problem on my end or

if it’s the blog. Any feed-back would be greatly appreciated.

Hello, I believe your web site might be having web browser compatibility problems.

When I take a look at your site in Safari,

it looks fine however, when opening in Internet Explorer,

it’s got some overlapping issues. I just wanted to give you a quick heads up!

Other than that, wonderful blog!

Wow! This blog looks just like my old one! It’s on a totally different subject but it has pretty much the same page layout

and design. Superb choice of colors!

This post will assist the internet people for creating new weblog or even a weblog from start to end.

Someone necessarily help to make critically articles I

would state. That is the first time I frequented your web page and

so far? I surprised with the research you made to

create this particular publish amazing. Excellent task!

Hello! This is my 1st comment here so I just wanted to give a quick shout out

and say I truly enjoy reading your posts.

Can you suggest any other blogs/websites/forums that cover

the same subjects? Thank you so much!

I visited various blogs except the audio feature for audio songs existing at this web page is actually superb.

Its such as you learn my mind! You appear to know a lot about this, like you wrote the book in it or something.

I think that you could do with a few % to force the message home a bit, but

instead of that, this is great blog. A great read.

I’ll certainly be back.

Your way of describing all in this piece of writing is truly nice, every one be able to without

difficulty understand it, Thanks a lot.

Wonderful blog! I found it while surfing around on Yahoo News.

Do you have any suggestions on how to get listed in Yahoo News?

I’ve been trying for a while but I never seem to get there!

Many thanks

When I initially commented I clicked the “Notify me when new comments are added” checkbox and now each time

a comment is added I get four e-mails with the same comment.

Is there any way you can remove people from that service?

Cheers!

We absolutely love your blog and find nearly all of your post’s to be exactly I’m looking for.

Would you offer guest writers to write content for yourself?

I wouldn’t mind composing a post or elaborating on many of the subjects you write regarding here.

Again, awesome website!

hey there and thank you for your information – I have certainly picked up anything new from right

here. I did however expertise a few technical points using this

website, as I experienced to reload the web site lots of times previous to I could get it

to load properly. I had been wondering if your web host is

OK? Not that I am complaining, but slow loading instances times will sometimes affect your placement in google

and can damage your quality score if ads and marketing with Adwords.

Anyway I’m adding this RSS to my email and can look out for a lot more of your respective intriguing content.

Make sure you update this again very soon.

Heya i am for the first time here. I came across this board and I find It truly useful & it helped me

out a lot. I hope to give something back and aid others

like you helped me.

Saved as a favorite, I like your web site!

I am regular visitor, how are you everybody? This paragraph posted at this website is

truly pleasant.

hello there and thank you for your information –

I have definitely picked up something new from right here.

I did however expertise some technical points using this web site, as I experienced to reload the website a lot of times

previous to I could get it to load correctly. I had been wondering if your hosting is OK?

Not that I am complaining, but slow loading instances times will sometimes affect your placement in google and could damage your quality score

if advertising and marketing with Adwords. Well I’m adding

this RSS to my e-mail and can look out for much more of your

respective interesting content. Ensure that you update

this again soon.

Nice weblog here! Also your site so much up fast!

What web host are you the use of? Can I am getting your affiliate hyperlink in your host?

I want my web site loaded up as quickly as yours

lol

Just want to say your article is as amazing.

The clarity to your submit is just nice and that i can suppose you are an expert in this subject.

Fine along with your permission let me to seize your feed to stay

up to date with forthcoming post. Thanks 1,000,000 and

please keep up the gratifying work.

Hey I know this is off topic but I was wondering if you knew of any widgets I could add to my blog that automatically tweet my newest

twitter updates. I’ve been looking for a plug-in like this

for quite some time and was hoping maybe you would have some experience with something like this.

Please let me know if you run into anything. I truly

enjoy reading your blog and I look forward to your new updates.

Helpful information. Fortunate me I found your website unintentionally, and I am surprised why this

coincidence did not took place in advance! I bookmarked it.

Superb, what a webpage it is! This weblog presents valuable

facts to us, keep it up.

Touche. Solid arguments. Keep up the good effort.

I was able to find good info from your blog articles.

Can I simply say what a relief to uncover someone

that really knows what they’re discussing on the net. You definitely know how to bring an issue to light and make

it important. A lot more people have to look at this and understand this side of your story.

I can’t believe you are not more popular given that you surely have the gift.

Does your site have a contact page? I’m having problems locating it but, I’d like to send you an e-mail.

I’ve got some creative ideas for your blog you might be interested in hearing.

Either way, great website and I look forward to seeing it improve over

time.

Write more, thats all I have to say. Literally, it seems as though you relied on the video to make

your point. You clearly know what youre talking about,

why throw away your intelligence on just posting videos to your site

when you could be giving us something informative to read?

This web site really has all of the info I needed

concerning this subject and didn’t know who to ask.

Hey I know this is off topic but I was wondering if you knew of any widgets I could add to my blog that

automatically tweet my newest twitter updates.

I’ve been looking for a plug-in like this for quite some time and was

hoping maybe you would have some experience with something

like this. Please let me know if you run into anything.

I truly enjoy reading your blog and I look forward to your new updates.

My family members all the time say that I am wasting my time here at net, except I know I am

getting familiarity daily by reading such nice content.

A person essentially lend a hand to make seriously articles I’d state.

This is the very first time I frequented your website

page and so far? I surprised with the research you made to make this

particular put up extraordinary. Fantastic activity!

Hey there! Do you use Twitter? I’d like to follow you if that would be okay.

I’m absolutely enjoying your blog and look forward to new updates.

I love it when people come together and share ideas. Great site,

continue the good work!

fantastic publish, very informative. I wonder why the other specialists of this sector don’t notice

this. You must proceed your writing. I am sure, you have

a huge readers’ base already!

Simply want to say your article is as surprising.

The clearness in your post is just nice and i could assume you are an expert on this

subject. Fine with your permission allow me to grab your feed to keep

updated with forthcoming post. Thanks a million and

please carry on the gratifying work.

always i used to read smaller articles which also clear

their motive, and that is also happening with

this piece of writing which I am reading at this time.

Heya great website! Does running a blog such as this

take a massive amount work? I have very little expertise in programming however I was hoping

to start my own blog in the near future. Anyhow, should you have any suggestions or techniques for

new blog owners please share. I understand this is off subject however I just wanted to ask.

Thanks!

It’s a shame you don’t have a donate button! I’d most certainly donate to

this brilliant blog! I suppose for now i’ll settle for book-marking and adding your RSS feed to my Google account.

I look forward to fresh updates and will talk about this website with my

Facebook group. Talk soon!

It’s appropriate time to make some plans for the longer term

and it is time to be happy. I have read this submit and if I may I wish to counsel you some interesting

issues or tips. Maybe you can write next articles regarding this article.

I want to read even more issues about it!

Excellent blog here! Also your web site loads up

fast! What web host are you using? Can I get your affiliate link to your host?

I wish my website loaded up as quickly as yours lol

When I originally commented I clicked the “Notify me when new comments are added” checkbox and

now each time a comment is added I get three emails with the same comment.

Is there any way you can remove people from that service?

Many thanks!

I love what you guys are usually up too. This type of clever work and exposure!

Keep up the terrific works guys I’ve included you guys to my personal blogroll.

I’m not that much of a online reader to be honest but your blogs really nice, keep it

up! I’ll go ahead and bookmark your website to come back later on. Many thanks

Attractive portion of content. I just stumbled upon your weblog and in accession capital to say that I

get in fact enjoyed account your blog posts. Anyway

I will be subscribing on your feeds or even I fulfillment you

get entry to constantly rapidly.

If you are going for finest contents like me, just pay a quick visit this website every

day since it gives feature contents, thanks

Heya exceptional blog! Does running a blog similar

to this take a lot of work? I have virtually no expertise

in computer programming but I had been hoping to start my own blog

soon. Anyways, should you have any recommendations or

techniques for new blog owners please share. I understand this is off subject nevertheless I simply had to ask.

Thanks a lot!

Fantastic goods from you, man. I’ve understand your stuff previous to and you’re just too great.

I actually like what you have acquired here, really like what you are stating and the way

in which you say it. You make it enjoyable and you still take care of to keep it sensible.

I cant wait to read far more from you. This is actually a terrific web site.

Sweet blog! I found it while searching on Yahoo News.

Do you have any suggestions on how to get listed in Yahoo News?

I’ve been trying for a while but I never seem to

get there! Cheers

Have you ever thought about adding a little bit more

than just your articles? I mean, what you say is

fundamental and all. However think about if you added some great photos or videos to give your posts more, “pop”!

Your content is excellent but with images

and clips, this site could undeniably be one of the very

best in its field. Excellent blog!

I’m not sure where you’re getting your info, but good topic.

I needs to spend some time learning more or understanding more.

Thanks for fantastic info I was looking for this information for my mission.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

We are a gaggle of volunteers and opening a brand new scheme

in our community. Your site offered us with valuable information to work on. You’ve performed a formidable job

and our whole group can be grateful to you.

Your means of telling the whole thing in this paragraph is in fact good, every one be

able to effortlessly know it, Thanks a lot.

Greate post. Keep writing such kind of info on your page.

Im really impressed by it.

Hi there, You’ve performed a fantastic job.

I will certainly digg it and in my view suggest to my friends.

I am sure they will be benefited from this site.

Usually I don’t learn post on blogs, however I wish to say that this

write-up very pressured me to check out and do it! Your writing style has

been surprised me. Thank you, very great article.

Thank you for the auspicious writeup. It in fact was a amusement account it.

Look advanced to far added agreeable from you!

However, how could we communicate?

Hurrah, that’s what I was searching for, what a information!

existing here at this weblog, thanks admin of

this web site.

Do you have a spam problem on this website; I also am a blogger,

and I was wanting to know your situation; many of us have created some nice

practices and we are looking to trade techniques with other

folks, why not shoot me an e-mail if interested.

My spouse and I stumbled over here by a different web address and thought I

should check things out. I like what I see so i am just following you.

Look forward to looking at your web page yet again.

I visited multiple blogs but the audio quality for audio songs

current at this website is genuinely marvelous.

Excellent beat ! I would like to apprentice whilst you amend your website, how could i

subscribe for a blog site? The account helped me a appropriate deal.

I had been tiny bit acquainted of this your broadcast provided vibrant transparent concept

I was suggested this web site by my cousin. I’m not sure whether this post is written by him as no one else know such detailed about my trouble.

You’re amazing! Thanks!

There is certainly a lot to find out about this issue. I love all the points you have made.

Hello everybody, here every one is sharing these kinds of familiarity, therefore it’s pleasant to read this blog, and I used to

pay a quick visit this blog daily.

obviously like your website but you have to

test the spelling on quite a few of your posts. A number of

them are rife with spelling problems and I in finding it very bothersome to

inform the reality however I will definitely come back again.

What’s up, after reading this remarkable post i am also delighted to share my

know-how here with friends.

I’ve been surfing online more than 2 hours today, yet I never found any interesting article like yours.

It is pretty worth enough for me. Personally, if all webmasters and bloggers made good content as

you did, the net will be a lot more useful than ever before.

I’m not that much of a internet reader to be honest but your blogs really nice, keep it up!

I’ll go ahead and bookmark your website to come back in the future.

Many thanks

Wow, marvelous blog layout! How long have you ever been running a blog

for? you made running a blog glance easy.

The overall look of your site is excellent, as

neatly as the content!

I’m not that much of a online reader to be honest but your blogs really nice,

keep it up! I’ll go ahead and bookmark your website to

come back later on. All the best

Hi! Someone in my Myspace group shared this website with us so I came to give

it a look. I’m definitely loving the information. I’m

book-marking and will be tweeting this to my followers!

Superb blog and terrific style and design.

Write more, thats all I have to say. Literally, it seems as

though you relied on the video to make your point.

You obviously know what youre talking about, why throw away your intelligence on just posting videos to your weblog when you

could be giving us something informative to read?

I’m not sure why but this blog is loading incredibly slow for me.

Is anyone else having this problem or is it a problem on my end?

I’ll check back later on and see if the problem still exists.

Greetings! I know this is kind of off topic but I was wondering which blog platform are you using for this website?

I’m getting sick and tired of WordPress because I’ve had issues with hackers and I’m looking at options for another platform.

I would be great if you could point me in the direction of a good

platform.

Attractive section of content. I just stumbled upon your web site and in accession capital to assert that I acquire actually enjoyed account

your blog posts. Anyway I will be subscribing to your feeds and even I achievement you access

consistently quickly.

We stumbled over here by a different page

and thought I might check things out. I like what I see so now i’m

following you. Look forward to looking at your

web page again.

Stunning quest there. What happened after? Take care!

I’ve read several good stuff here. Definitely price bookmarking for

revisiting. I wonder how a lot attempt you put to create one of these fantastic

informative site.

Hey there this is kinda of off topic but I was wondering

if blogs use WYSIWYG editors or if you have to manually code with HTML.

I’m starting a blog soon but have no coding skills so I wanted to get advice from someone with experience.

Any help would be enormously appreciated!

I love your blog.. very nice colors & theme. Did you create

this website yourself or did you hire someone to do it for you?

Plz respond as I’m looking to construct my own blog and would like

to find out where u got this from. thanks a lot

Hmm is anyone else encountering problems with the images

on this blog loading? I’m trying to figure out if its a problem on my end or if it’s the

blog. Any responses would be greatly appreciated.

I know this if off topic but I’m looking into

starting my own blog and was curious what all is required to get set up?

I’m assuming having a blog like yours would cost a pretty penny?

I’m not very internet smart so I’m not 100% certain. Any recommendations or advice would be greatly appreciated.

Thank you

This is really fascinating, You are an overly professional blogger.

I’ve joined your rss feed and look forward to in search of extra of your fantastic post.

Additionally, I have shared your web site in my social

networks

No matter if some one searches for his essential thing, so he/she desires to be available that in detail, therefore that

thing is maintained over here.

Thanks to my father who told me on the topic of this weblog, this web site is really

amazing.

I think the admin of this site is actually working hard in favor of his

website, because here every information is quality

based data.

My relatives all the time say that I am killing my time here at web, but I know I am getting knowledge all the time by reading thes pleasant articles or reviews.

Great information. Lucky me I ran across your site by accident

(stumbleupon). I have book-marked it for later!

What’s Taking place i’m new to this, I stumbled upon this I have found It absolutely useful and it has helped

me out loads. I’m hoping to contribute & help other users like

its aided me. Great job.

You really make it appear really easy with your presentation however I to

find this topic to be really one thing which I believe I would never

understand. It kind of feels too complex and extremely vast for me.

I’m looking forward to your subsequent publish, I will try to

get the hold of it!

My partner and I absolutely love your blog and find the majority of your post’s to

be precisely what I’m looking for. Does one offer guest writers to write content for you?

I wouldn’t mind composing a post or elaborating on many of the subjects you write about

here. Again, awesome site!

I’m gone to inform my little brother, that he should also

pay a visit this blog on regular basis to obtain updated from most up-to-date news update.

This paragraph is actually a pleasant one it helps new the web visitors, who

are wishing in favor of blogging.

I absolutely love your site.. Very nice colors & theme.

Did you build this web site yourself? Please reply back as I’m attempting to create my own blog and would like to know where you

got this from or just what the theme is called.

Cheers!

Heya! I’m at work surfing around your blog from my new iphone 4!

Just wanted to say I love reading through your blog and look forward

to all your posts! Keep up the fantastic work!

Everyone loves what you guys are usually up too. This sort of clever work and

coverage! Keep up the amazing works guys I’ve added you guys to my

blogroll.

Hi there very cool website!! Guy .. Excellent ..

Superb .. I will bookmark your website and take the feeds additionally?

I’m happy to find a lot of useful information right here

within the submit, we’d like work out more strategies in this regard, thank

you for sharing. . . . . .

Hi there everyone, it’s my first pay a visit at this website,

and post is genuinely fruitful in support of me, keep up posting such articles or reviews.

Hello, i think that i saw you visited my website thus i came to “return the favor”.I’m attempting to find things

to enhance my site!I suppose its ok to use a few of your ideas!!

Quality content is the secret to interest the

users to pay a quick visit the web page, that’s what

this site is providing.

When I initially commented I clicked the “Notify me when new comments are added” checkbox and now each time

a comment is added I get four emails with

the same comment. Is there any way you can remove me from that service?

Cheers!

I really like your blog.. very nice colors & theme. Did you make this website yourself or did you hire someone

to do it for you? Plz answer back as I’m looking to create my own blog and would like

to find out where u got this from. thanks a lot

Awesome issues here. I’m very satisfied to see your post.

Thank you so much and I am taking a look ahead to touch you.

Will you please drop me a mail?

I’ve been surfing on-line greater than 3 hours as of late, but I by no means discovered any fascinating article like yours.

It is pretty price sufficient for me. In my view, if all website

owners and bloggers made excellent content material as you probably did, the web will likely be much more helpful than ever before.

Do you have any video of that? I’d like to find out more details.

What’s up everyone, it’s my first visit at this web page, and article is in fact fruitful

for me, keep up posting these content.

This design is incredible! You most certainly know how

to keep a reader amused. Between your wit and your videos, I was

almost moved to start my own blog (well, almost…HaHa!)

Great job. I really loved what you had to say,

and more than that, how you presented it. Too cool!

Excellent weblog here! Additionally your site a lot up fast!

What host are you using? Can I get your affiliate hyperlink in your host?

I desire my website loaded up as quickly as yours lol

WOW just what I was looking for. Came here by searching for naga169

Hello, I wish for to subscribe for this web site to obtain newest updates,

so where can i do it please assist.

Hello there, You’ve done a fantastic job.

I’ll certainly digg it and personally recommend to

my friends. I’m sure they’ll be benefited from this

website.

Thankfulness to my father who shared with me concerning this website, this web site is really

remarkable.

When I originally commented I appear to have clicked on the -Notify me when new comments are added- checkbox and now whenever a comment is added I receive

four emails with the exact same comment. There has to be a means you are

able to remove me from that service? Many thanks!

Howdy are using WordPress for your blog platform?

I’m new to the blog world but I’m trying to get started and set up my own. Do

you need any coding knowledge to make your own blog? Any help would

be greatly appreciated!

Excellent goods from you, man. I’ve understand your stuff prior to

and you are simply too fantastic. I actually like what you’ve obtained

here, really like what you’re stating and the best way in which you

are saying it. You are making it entertaining and you still care for

to keep it wise. I cant wait to read much more from you.

This is really a tremendous website.

Hello to all, how is everything, I think every one is getting more from this web site, and your views are pleasant

designed for new people.

I do not even know how I ended up here, but I thought this post was great.

I do not know who you are but certainly you are going

to a famous blogger if you aren’t already 😉 Cheers!

I like what you guys are up too. This type of clever work and reporting!

Keep up the fantastic works guys I’ve included you guys to my own blogroll.

Hi fantastic website! Does running a blog like

this take a massive amount work? I have no understanding

of computer programming however I was hoping to start

my own blog soon. Anyways, should you have any suggestions

or tips for new blog owners please share.

I understand this is off subject but I simply

wanted to ask. Thanks!

For the reason that the admin of this site is

working, no hesitation very rapidly it will be renowned, due to its feature contents.

My partner and I absolutely love your blog and find the majority of your post’s

to be what precisely I’m looking for. can you offer guest writers to write content available for you?

I wouldn’t mind publishing a post or elaborating on a

number of the subjects you write regarding here. Again, awesome website!

Very energetic post, I loved that a lot. Will there be a part

2?

Hi there just wanted to give you a quick heads up. The words in your content seem to be running off the screen in Firefox.

I’m not sure if this is a formatting issue or something to do with browser

compatibility but I figured I’d post to let you know.

The style and design look great though! Hope you get the problem resolved soon. Kudos

Simply desire to say your article is as amazing.

The clarity in your submit is just great and

i could think you are an expert on this subject.

Fine together with your permission let me to seize your feed

to stay updated with impending post. Thank you a million and please keep up the rewarding work.

I’m gone to convey my little brother, that he

should also visit this website on regular basis to take

updated from most up-to-date news.

Hey! I just wanted to ask if you ever have any problems with hackers?

My last blog (wordpress) was hacked and I ended up losing months of hard work due to no data backup.

Do you have any solutions to prevent hackers?

Aw, this was an extremely good post. Spending some time and actual

effort to generate a superb article… but what can I say… I procrastinate a whole lot

and never seem to get anything done.

After looking at a handful of the blog posts on your web site, I honestly like your

way of writing a blog. I added it to my bookmark webpage list and

will be checking back soon. Please visit my web site as well and let me know how you feel.

When I initially commented I clicked the “Notify me when new comments are added” checkbox and now each time a comment is added I get

three e-mails with the same comment. Is there any

way you can remove people from that service? Cheers!

Great info. Lucky me I came across your blog by chance (stumbleupon).

I have bookmarked it for later!

Hey there I am so excited I found your webpage, I really found

you by error, while I was browsing on Bing for something else, Regardless I am here now and would just like to say cheers

for a tremendous post and a all round exciting blog (I

also love the theme/design), I don’t have time to read it all at the minute

but I have book-marked it and also added in your RSS feeds, so when I have time I will be back to read much more, Please do keep up the awesome job.

I like the helpful info you provide in your articles. I’ll

bookmark your weblog and check again here regularly.

I’m quite certain I’ll learn many new stuff right here!

Good luck for the next!

obviously like your website however you have to check the spelling on several of your posts.

A number of them are rife with spelling problems

and I in finding it very troublesome to tell the truth on the other hand I’ll surely come back again.

Thank you for the auspicious writeup. It in fact was a amusement account

it. Look advanced to more added agreeable from you! By the

way, how could we communicate?

I want to to thank you for this very good read!! I certainly loved every bit of it.

I’ve got you saved as a favorite to check out new things you post…

Very good article! We will be linking to this

particularly great post on our website. Keep up the great writing.

My developer is trying to persuade me to move to .net from PHP.

I have always disliked the idea because of the costs.

But he’s tryiong none the less. I’ve been using Movable-type

on a number of websites for about a year and am nervous

about switching to another platform. I have

heard very good things about blogengine.net. Is there a way I can import all my wordpress posts into it?

Any help would be greatly appreciated!

You should be a part of a contest for one of the finest websites on the internet.

I will highly recommend this website!

It is really a nice and useful piece of info. I’m happy that you shared

this useful information with us. Please keep us informed like this.

Thanks for sharing.

Excellent blog! Do you have any recommendations for aspiring writers?

I’m hoping to start my own website soon but I’m a little lost on everything.

Would you propose starting with a free platform like

Wordpress or go for a paid option? There are

so many options out there that I’m totally confused .. Any ideas?

Thanks a lot!

whoah this weblog is wonderful i like reading your posts.

Stay up the great work! You recognize, many persons are hunting round

for this information, you could help them greatly.

It’s very trouble-free to find out any topic on web as compared to textbooks, as I found this paragraph at this web

page.

Wow that was odd. I just wrote an very long comment but after I

clicked submit my comment didn’t show up.

Grrrr… well I’m not writing all that over again. Anyhow, just wanted

to say superb blog!

Hey very interesting blog!

Excellent blog you have here.. It’s hard to find good quality writing like yours

nowadays. I seriously appreciate people like you! Take care!!

Your style is very unique compared to other people I have read stuff from.

Thanks for posting when you have the opportunity, Guess

I’ll just book mark this site.

Hello There. I found your blog using msn. This is a really well written article.

I will make sure to bookmark it and come back to

read more of your useful info. Thanks for the post. I will certainly return.

I am truly thankful to the owner of this web page who has shared this enormous article at here.

Hi, I do think this is a great website. I stumbledupon it 😉 I am

going to revisit once again since i have book-marked it. Money and freedom is the best

way to change, may you be rich and continue to guide other people.

I’m not sure why but this site is loading incredibly slow for me.

Is anyone else having this issue or is it a issue on my end?

I’ll check back later on and see if the problem still exists.

I was able to find good advice from your content.

Just want to say your article is as astonishing. The clarity on your post is simply great and i could assume you are knowledgeable in this

subject. Fine together with your permission allow me to clutch your

RSS feed to keep updated with impending post.

Thanks one million and please carry on the enjoyable work.

I was suggested this blog by my cousin. I’m not sure

whether this post is written by him as no one

else know such detailed about my difficulty. You are wonderful!

Thanks!

For most recent news you have to go to see world wide web and on the web I found this web

site as a most excellent web page for hottest updates.

Excellent way of describing, and pleasant

paragraph to get data on the topic of my presentation subject matter, which

i am going to present in institution of higher education.

Thank you, I’ve just been searching for info approximately this

topic for ages and yours is the greatest I have

found out till now. But, what in regards to the bottom line?

Are you sure concerning the supply?

Thanks for finally talking about > Design of a Doubly Reinforced Beam to Eurocode 2 – Worked Example –

First Principle Engineering < Liked it!

I’m gone to convey my little brother, that he should also go to see this website

on regular basis to get updated from latest reports.

Everything is very open with a really clear clarification of

the issues. It was definitely informative. Your site is very useful.

Thanks for sharing!

Thank you, I have recently been searching for info approximately this topic for ages and yours is the greatest I’ve discovered so

far. But, what about the bottom line? Are you positive concerning the

source?

What’s up, yup this piece of writing is in fact fastidious and I have learned lot of things from it on the topic of blogging.

thanks.

Very descriptive post, I enjoyed that bit. Will there be a part 2?

I’m impressed, I have to admit. Seldom do I come

across a blog that’s both equally educative and engaging, and let me tell you, you’ve hit the nail on the head.

The issue is something not enough people are speaking intelligently about.

Now i’m very happy that I found this in my search for something regarding this.

Does your website have a contact page? I’m having trouble locating it but, I’d like to shoot you an email.

I’ve got some creative ideas for your blog you might be interested in hearing.

Either way, great website and I look forward to seeing it grow over time.

Thanks for sharing your thoughts. I truly

appreciate your efforts and I will be waiting

for your further post thank you once again.

We are a bunch of volunteers and opening a new scheme in our community.

Your website offered us with useful info to work on. You have performed a formidable

process and our whole neighborhood will be grateful to you.

I am regular reader, how are you everybody? This paragraph posted at this web page is genuinely good.

I couldn’t refrain from commenting. Well written!

Awesome! Its genuinely remarkable post, I have got much clear idea about from this article.

First of all I want to say superb blog! I had a quick

question that I’d like to ask if you don’t mind. I was curious to

find out how you center yourself and clear your mind prior to writing.

I have had a hard time clearing my mind in getting my thoughts out.

I do take pleasure in writing however it just seems like the

first 10 to 15 minutes are usually lost simply just trying to figure out how to begin. Any recommendations or hints?

Thanks!

Useful info. Fortunate me I discovered your website unintentionally, and I am shocked why this coincidence did not happened in advance!

I bookmarked it.

Awesome! Its really remarkable post, I have got much clear idea on the topic of from this post.

It’s actually a nice and helpful piece of information. I’m glad that you just shared this useful information with us.

Please keep us up to date like this. Thanks for sharing.

Please let me know if you’re looking for a article writer for your weblog.

You have some really good posts and I feel I would be a good asset.

If you ever want to take some of the load off, I’d absolutely love to write some articles for

your blog in exchange for a link back to mine. Please

shoot me an e-mail if interested. Kudos!

Good day! I know this is somewhat off topic but I was wondering if you knew where I could find a captcha plugin for my comment

form? I’m using the same blog platform as yours and I’m having trouble

finding one? Thanks a lot!

Write more, thats all I have to say. Literally, it seems as though you relied on the video to make your point.

You clearly know what youre talking about, why throw away your intelligence on just posting videos to your site when you could be giving

us something enlightening to read?

Hi there colleagues, its wonderful article regarding teachingand completely explained, keep it up all

the time.

I could not resist commenting. Perfectly written!

I am not sure where you’re getting your information, but good topic.

I needs to spend some time learning much more or understanding more.

Thanks for fantastic info I was looking for this

information for my mission.

Thanks for sharing your thoughts. I really appreciate

your efforts and I will be waiting for your next write ups thank you once again.

Howdy! I could have sworn I’ve visited your blog before but after

browsing through many of the posts I realized it’s new to me.

Anyways, I’m certainly pleased I came across it and I’ll be bookmarking it and checking back regularly!

What a information of un-ambiguity and preserveness of valuable familiarity regarding unpredicted

emotions.

Hello there! I know this is kind of off topic but I was wondering which blog platform are you using

for this site? I’m getting tired of WordPress

because I’ve had issues with hackers and I’m looking

at alternatives for another platform. I would be fantastic

if you could point me in the direction of a good platform.

There’s certainly a lot to know about this subject.

I like all the points you made.

I wanted to thank you for this good read!! I absolutely enjoyed every bit of

it. I’ve got you book marked to look at new things you post…

Hello to every one, the contents existing at this site are really awesome for people

experience, well, keep up the nice work fellows.

What’s Happening i am new to this, I stumbled

upon this I’ve discovered It absolutely helpful and it

has helped me out loads. I’m hoping to contribute & aid other users like its helped

me. Good job.

Do you have a spam problem on this site; I also am a blogger, and I was wondering your situation; many of us have developed some nice practices and we are looking to swap strategies with other folks, why not shoot me an e-mail if interested.

Ahaa, its nice conversation regarding this post here at this webpage,

I have read all that, so now me also commenting here.

Excellent blog here! Also your web site rather a lot up very fast!

What host are you the use of? Can I am getting your affiliate hyperlink for your host?

I want my website loaded up as quickly as yours lol

I know this if off topic but I’m looking into

starting my own weblog and was wondering what all

is needed to get set up? I’m assuming having

a blog like yours would cost a pretty penny?

I’m not very web savvy so I’m not 100% positive.

Any tips or advice would be greatly appreciated. Thank you

If some one wishes to be updated with newest technologies then he must be go to see this website

and be up to date daily.

I enjoy what you guys are up too. This kind of clever

work and reporting! Keep up the superb works

guys I’ve you guys to blogroll.

Generally I don’t read article on blogs, however I wish to say that this write-up

very compelled me to try and do it! Your writing style has been surprised me.

Thanks, very great article.

Hello very cool website!! Man .. Excellent ..

Amazing .. I will bookmark your site and take the feeds additionally?

I am satisfied to search out so many useful info right here in the submit,

we’d like develop more strategies in this regard, thank you for sharing.

. . . . .

An outstanding share! I have just forwarded this onto a coworker who was conducting a

little research on this. And he in fact ordered me breakfast because I stumbled upon it for him…

lol. So allow me to reword this…. Thank YOU

for the meal!! But yeah, thanks for spending some time to discuss this matter here

on your web page.

I like the helpful information you supply to your articles.

I’ll bookmark your blog and check again here regularly.

I’m quite certain I’ll be informed a lot of new stuff proper here!

Good luck for the following!

I’m amazed, I must say. Seldom do I come across a blog that’s both equally

educative and engaging, and without a doubt, you’ve hit the nail on the head.

The problem is something not enough men and women are speaking intelligently

about. I am very happy that I found this during my search for something relating to this.

Very soon this web page will be famous amid all blogging and site-building users, due to it’s pleasant articles

Hey! This post couldn’t be written any better! Reading through this post reminds me of

my old room mate! He always kept chatting about

this. I will forward this write-up to him. Fairly certain he

will have a good read. Thanks for sharing!

Hi there everyone, it’s my first pay a visit at this web page, and paragraph is in fact fruitful for me,

keep up posting such posts.

I am regular visitor, how are you everybody? This paragraph posted at this website is truly good.

When I initially commented I clicked the “Notify me when new comments are added” checkbox and now each time a

comment is added I get three e-mails with the same comment.

Is there any way you can remove people from that service?

Cheers!

Excellent article. I will be facing a few of these issues as well..

Hey there! I’ve been following your blog for a while now

and finally got the courage to go ahead and give you a shout out from Austin Tx!

Just wanted to tell you keep up the excellent work!

Pretty section of content. I just stumbled upon your website and in accession capital to assert

that I acquire in fact enjoyed account your blog posts.

Anyway I will be subscribing to your augment and even I achievement you access consistently fast.

It’s awesome in favor of me to have a web site, which is

helpful in favor of my experience. thanks admin

Useful information. Lucky me I discovered your web site unintentionally, and I’m stunned why this

accident did not happened earlier! I bookmarked it.

Hi there, its fastidious article concerning media

print, we all know media is a enormous source

of data.

Have you ever considered writing an ebook or guest authoring on other sites?

I have a blog based on the same ideas you discuss and would really like

to have you share some stories/information. I know my audience would enjoy your work.

If you are even remotely interested, feel free to shoot me an e mail.

Pretty great post. I simply stumbled upon your blog and wanted to say that

I have truly loved browsing your blog posts.

After all I’ll be subscribing for your rss feed and

I hope you write once more soon!

Hi there! This blog post couldn’t be written much better!

Reading through this article reminds me of my previous roommate!

He constantly kept preaching about this. I most certainly will forward this information to him.

Pretty sure he’ll have a great read. Thank you for sharing!

Hmm it appears like your blog ate my first comment (it was super long) so I guess I’ll just sum it up

what I wrote and say, I’m thoroughly enjoying your blog.

I as well am an aspiring blog blogger but I’m still new to everything.

Do you have any tips for rookie blog writers?

I’d really appreciate it.

Inspiring quest there. What happened after? Good luck!

Very shortly this site will be famous among all blogging and site-building

users, due to it’s good content

WOW just what I was searching for. Came here by searching for xnxx

videos

Informative article, exactly what I needed.

My family members always say that I am wasting my time here at net, however I know I am getting experience everyday

by reading thes fastidious content.

Hi! Someone in my Facebook group shared this website with us so

I came to give it a look. I’m definitely loving the information. I’m bookmarking and

will be tweeting this to my followers! Wonderful blog and excellent design.

Hello friends, nice post and nice arguments commented here,

I am really enjoying by these.

I love your blog.. very nice colors & theme. Did you design this website yourself or did you hire someone to do it for you?

Plz reply as I’m looking to design my own blog and would like

to know where u got this from. kudos

I do agree with all of the ideas you have offered for your post.

They are really convincing and can definitely work.

Nonetheless, the posts are too brief for beginners. May just you please extend

them a bit from next time? Thank you for the post.

Your style is really unique compared to other folks I’ve read

stuff from. I appreciate you for posting when you have the opportunity, Guess I’ll just bookmark

this site.

Wow that was odd. I just wrote an incredibly long comment but after I clicked submit my comment didn’t show up.

Grrrr… well I’m not writing all that over

again. Anyways, just wanted to say fantastic blog!

Hey there, I think your site might be having browser compatibility issues.

When I look at your blog site in Firefox, it looks fine

but when opening in Internet Explorer, it has some overlapping.

I just wanted to give you a quick heads up!

Other then that, great blog!

Hi! I know this is somewhat off topic but I was wondering which blog platform are you using

for this website? I’m getting tired of WordPress because

I’ve had problems with hackers and I’m looking at options

for another platform. I would be awesome if you could point me in the direction of a good

platform.

Incredible points. Sound arguments. Keep up the amazing spirit.

Way cool! Some extremely valid points! I appreciate you penning this article and the rest of the site is extremely good.

hi!,I love your writing very much! proportion we keep in touch more

approximately your post on AOL? I require a specialist on this house to unravel my problem.

Maybe that’s you! Taking a look ahead to look you.

Hey There. I found your blog using msn. This is a really well

written article. I will be sure to bookmark it and come back to read more of your useful info.

Thanks for the post. I’ll definitely comeback.

Hello There. I found your blog using msn. This is a very well written article.

I’ll make sure to bookmark it and return to read more of

your useful info. Thanks for the post. I’ll definitely return.

you are truly a good webmaster. The website loading speed is

amazing. It sort of feels that you are doing any distinctive trick.

Furthermore, The contents are masterwork.

you’ve performed a great activity in this matter!

As the admin of this web site is working, no hesitation very shortly

it will be well-known, due to its quality contents.

Wonderful article! We are linking to this particularly

great post on our website. Keep up the great writing.

We stumbled over here by a different website and thought I should check things out.

I like what I see so now i am following you. Look forward to going

over your web page again.

Very soon this web page will be famous amid all blogging users,

due to it’s good articles

Touche. Solid arguments. Keep up the amazing spirit.

Hello there, I found your website by way of Google whilst looking for a similar topic, your site came up,

it seems good. I have bookmarked it in my google bookmarks.

Hi there, simply become alert to your weblog through Google, and located that

it is really informative. I’m going to watch out for brussels.

I will be grateful if you proceed this in future.

A lot of other folks will likely be benefited out of your writing.

Cheers!

This is really attention-grabbing, You’re an overly skilled blogger.

I have joined your rss feed and sit up for in quest of more

of your excellent post. Additionally, I’ve shared your site in my social networks

I know this if off topic but I’m looking into starting my own blog and was curious what all is required to get set up?

I’m assuming having a blog like yours would cost a pretty penny?

I’m not very web savvy so I’m not 100% positive. Any tips or advice would be greatly appreciated.

Kudos

I have read so many articles or reviews on the topic of the blogger lovers however this piece

of writing is really a pleasant paragraph, keep it up.

Hi, I think your blog might be having browser compatibility

issues. When I look at your blog in Opera, it looks fine but when opening in Internet Explorer, it has some overlapping.

I just wanted to give you a quick heads up!

Other then that, amazing blog!

Nice blog here! Also your site loads up very fast! What web host are you using?

Can I get your affiliate link to your host? I wish my site loaded up as quickly

as yours lol

Hey just wanted to give you a brief heads up and let you know a few

of the images aren’t loading properly. I’m not

sure why but I think its a linking issue. I’ve tried it in two different web browsers and

both show the same results.

I used to be recommended this blog by my cousin. I am no longer sure whether or not this submit is written by means of him as

no one else recognise such special about my problem.

You’re wonderful! Thank you!

Good post. I learn something totally new and challenging on blogs I stumbleupon on a daily basis.

It’s always interesting to read articles from other authors and use

a little something from other web sites.

Excellent way of telling, and fastidious piece of writing to obtain information on the topic of my presentation focus, which i am going to convey in college.

What a stuff of un-ambiguity and preserveness of valuable familiarity regarding

unexpected feelings.

I every time used to study piece of writing in news papers but now as I am a user of net so

from now I am using net for content, thanks to web.

Please let me know if you’re looking for a article writer for your site.

You have some really good posts and I think I would be

a good asset. If you ever want to take some of the load off, I’d absolutely love to write

some articles for your blog in exchange for a link back to mine.

Please shoot me an e-mail if interested. Regards!

It’s hard to find knowledgeable people in this particular subject, but you sound like you know what you’re

talking about! Thanks

Hey there! Would you mind if I share your blog with my myspace group?

There’s a lot of people that I think would really appreciate your content.

Please let me know. Thank you

Hello, Neat post. There is an issue along with your web site

in web explorer, may test this? IE still is the marketplace chief

and a good component to people will omit your magnificent writing because of this problem.

You really make it seem so easy with your presentation however I in finding this matter to be actually one thing that I think I’d by no means understand.

It sort of feels too complicated and very huge for me.

I am looking ahead on your subsequent publish, I’ll try to get the hold of it!

Howdy I am so happy I found your webpage, I really found you by accident, while I was looking on Google

for something else, Nonetheless I am here now and would